Setting up for machine control

From the Home menu, tap Project Setup / Machine Control Setup  .

.

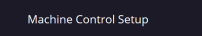

To set up the instrument for a Trimble GCS900 or Earthworks machine control system, select Machine Control Mode in the Instrument Mode dropdown menu. If the instrument has the OEM option installed, an OEM mode is available. For this option to be available, you must be connected to a total station .

Defining the window for Full Search mode

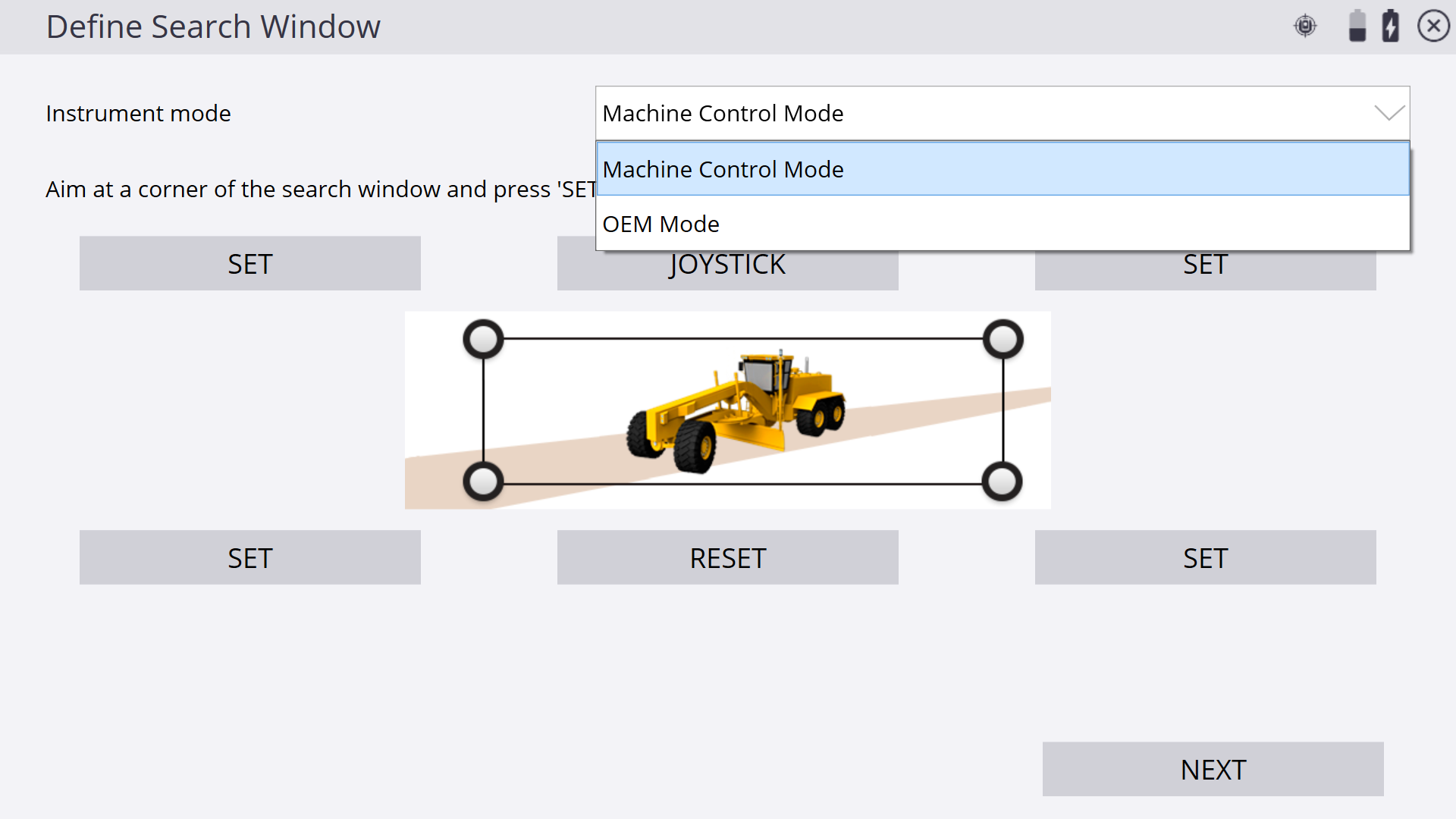

When defining the window for the Full Search mode:

-

Accommodate the fact that the prism can be mounted on an electric mast, and that the vertical window of operation at close range will be higher or lower than at longer ranges.

-

Ensure that you set the window of operation to cover the extents of all grading operations to be completed from that location's instrument setup.

-

Ensure that if the machine is taken outside that window, to turn around or to bench on a known height point, those locations are also included in the search window.

You can define either the upper left/lower right extents of your search window or the upper right/lower left extents of your search window. Ensure that you take a good look at any high or low points in the area where you will be working and then define your search window to what most closely resembles the actual working area in front of the instrument.

-

Point the total station to an upper left location and then to a lower right location; tap the appropriate Set button at each pointing.

-

Point the total station to an upper right location and then to a lower left location, tapping the appropriate Set button at each pointing.

You can use the joystick function, or physically turn the total station by hand to aim at the corner points. To use the joystick to set the corner points, tap JOYSTICK and use the joystick commands to point the total station to one corner. When the total station is pointed in the correct corner, tap ACCEPT in the Joystick window to return to the Define Search Window, and then hit the appropriate corner’s Set button. Repeat this process for the opposite corner.

As soon as the first corner is defined, the only option available in the software is to define the opposite corner. For example, if you define the upper right extent first, the lower left corner only is made available to define. If the lower right corner is set first, then the upper left corner only is made available to define.

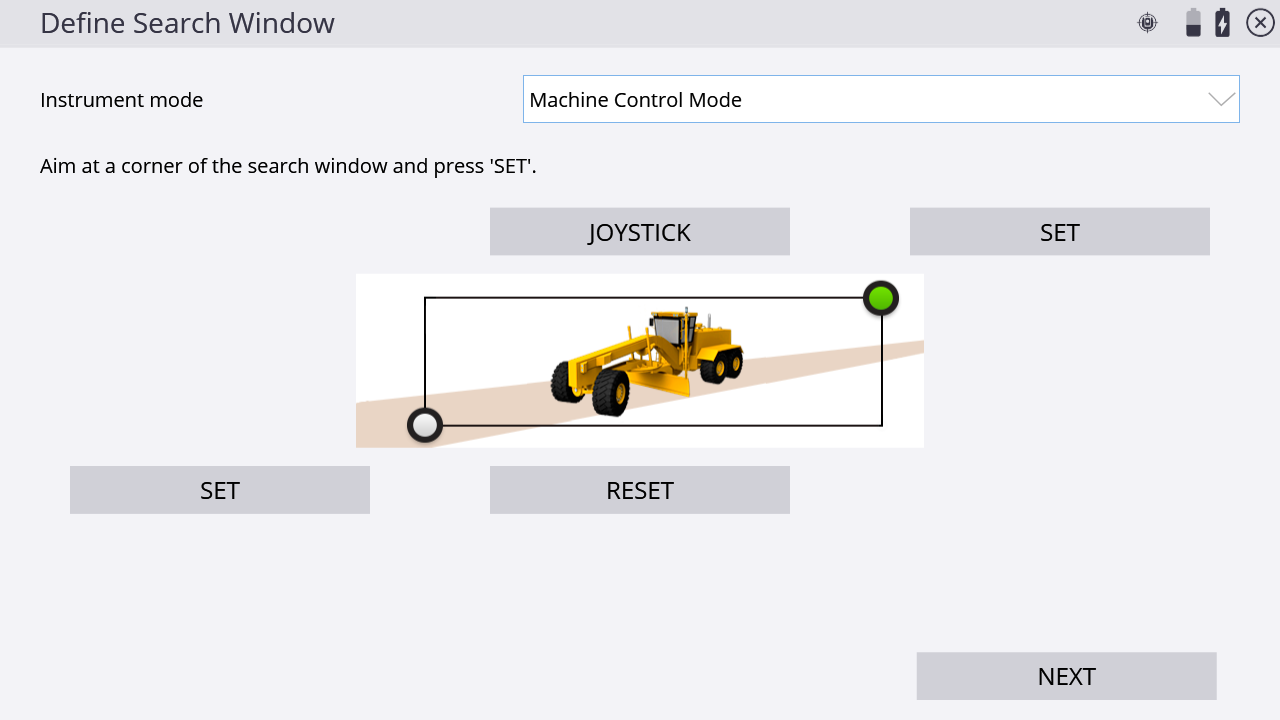

A single SPSx30 total station can be shared by multiple machines and a single SPS robotic rover pole. Only one user can use the total station at a time, but when not in use, it continually scans a predefined list of radio channels assigned to different machines and the last used site positioning system channel in sequence, looking to see if anyone needs access to the total station. When a machine or site positioning system calls the total station, it connects and provides a positioning service. When completed, the total station returns to Standby mode and becomes available to the radio channels previously loaded to the instrument. Note that this process is made easier in Siteworks software by tapping the Disconnect button in the Project Setup menu after the Siteworks uses are complete. To facilitate this process, in the set up for machine control process, you can create a list of machines, each with a name and a specified radio channel, for example:

-

CAT 140H Grader 1 33

-

CAT D6 Dozer 1 34

The machine list is scanned sequentially whenever the total station is placed in Standby mode for machine control. The more entries in the list, the longer the scan takes to complete a full cycle and therefore the slower the initial connection will be with the total station. If you are not continually using the entries in the list in earthmoving operations, delete the entries from the list to speed up initial connection times.

Tap the + icon to create a machine in the machine list, enter a machine name and assign a network channel. Also, select a Network ID for the instrument.

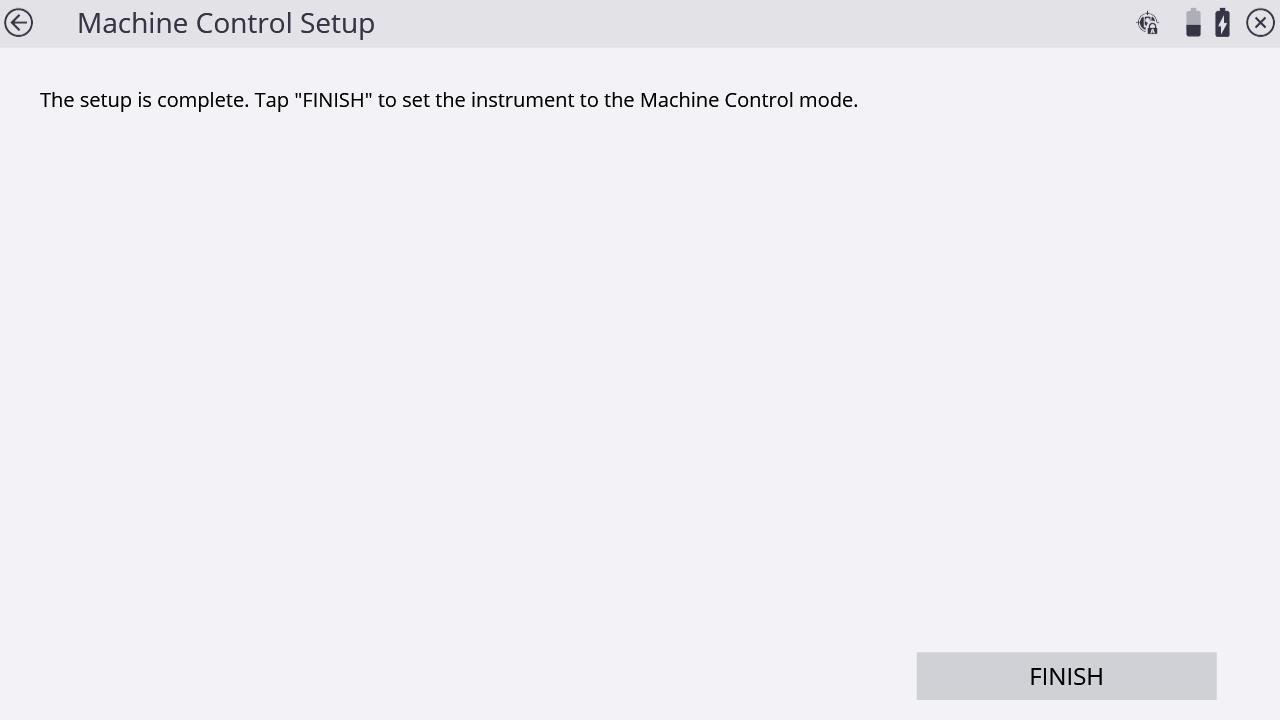

This completes the instrument setup. The total station goes into Standby mode waiting for a machine to connect to it. Tap NEXT to confirm the machine control setup. The following screen appears:

The total station goes into Standby mode for machine control and then it scans the machine list in chronological order until a machine is found calling the instrument on one of the channels. The software now disconnects from the total station. Move to the machine and initiate connection to the total station from the machine's grade control software.

If a machine control setup has already been performed at a given station setup, and the total station has not been moved to a new location or had a new station setup performed, when entering the Machine Control Setup screen, a prompt appears asking if you would like to use the machine control settings already saved to the instrument. Selecting YES will use the same search window and machine ID previously configured. Selecting NO will enter into the machine control setup workflow again.

If you are tracking a machine and the target becomes lost for any reason, the total station continues to turn at a constant horizontal and vertical speed for a short period, in the expectation that the target will appear on the same trajectory when it clears the obstruction. A line-of-sight obstruction, a passing vehicle, or simply losing the target because of movement speed can cause the total station to lose the target. When the target is 'lost', that is, the above method failed to reacquire the target, the total station searches for the target. The total station has two search modes:

|

Mode |

Description |

|---|---|

|

Quick Search |

Initiated as soon as the target is 'lost'. This search is centered on the last known location, and inside a window defined by a horizontal angle width (for example, 15°) and a vertical angle width (for example, 15°). The machine control software sets the values for the search window. |

|

Full Search |

This search looks inside a larger window, defined by the screen shown previously. When the Quick Search mode fails to locate the target, the Full Search mode is initiated. |

If you are operating at the total station, point it at the MT900 target on the machine. When the machine connects to the total station, this speeds up the initial search and lock-on process for the total station as it instantly “sees” the target and locks to it.