Create a Corridor Mass Haul Analysis

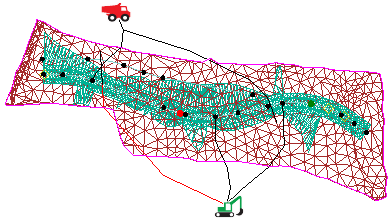

Use the Create Corridor Mass Haul Analysis command to determine the most efficient way to redistribute earthen material from cut zones to fill zones along a corridor construction job. The resulting Corridor Mass Haul Diagram is derived from a cumulative plot of cut minus fill. If cut exactly balances fill over the diagram, the accumulated imbalance in the plot also indicates the volume of material being moved past any point, and the direction of movement.

- A surplus of cut (above the axis) at a point means that you must move the surplus material past that point toward the finish.

- A deficit of material (below the axis) at a point means that you must move material toward the start to make up the deficit.

However, mass haul is usually not as simple as the situation described above. One or more of the following factors may apply:

- Features, such as an unbridged river, can form a barrier that prevent material from being hauled past, and divide the alignment into independent sections.

- Some cut may be unsuitable for use as fill and must be dumped.

- Cut and fill may not balance exactly within the sections.

- Waste sites provide locations where unwanted material can be disposed of.

- Borrow sites provide locations where extra material can be acquired.

- Processing sites are locations where material can be processed and converted into different materials.

- Material may be exported for some external purpose, such as overpass ramps, and provided at no cost. This material must be sourced and transported as part of the overall earthmoving task.

- Material may be imported from some external sources and may need to be transported and used, or dumped as part of the overall earthmoving task.

- Material may be hauled along haul roads to other sections of the alignment to circumvent barriers.

- There may be a maximum distance that each vehicle can economically haul material.

Imbalances between cut and fill on an alignment are resolved at waste sites, processing sites and borrow sites, and their location affects the direction that material flows. As a result of these factors, usable and unusable material may move in opposite directions past some points and need to be accounted for separately.

There are several tools that can be used to assist in the management of mass haul and materials: barriers, export locations, import locations, borrow sites, waste sites, processing sites, haul roads, haul ranges, auto-balance, and balance at grade point, all of which have a different impact on the mass haul analysis for the corridor.

Prerequisites:

- License; See the Subscription Plans page. For a license matrix by command, see the License page in the TBC Community. Also see View and manage licensed features.

- Corridor

- In situ earthen material with shrinkage and bulkage factors defined, if you want a more precise analysis.

- Digital or paper maps identifying any of these that apply:

- Barriers

- Export locations

- Import locations

- Haul roads

- Borrow pits

- Waste sites

- Processing sites

- Haul ranges for vehicles

To access the command:

- Select Create Corridor Mass Haul Analysis in Corrior Mass Haul > Analysis.

- Right-click a corridor in the Project Explorer, and select Create Corridor Mass Haul Analysis from the context menu.

To Create a corridor mass haul:

- In the Name box, type an identifier for the mass haul analysis as you want it to appear in the Project Explorer and Corridor Mass Haul Report.

- Confirm the corridor along which you want to analyze earthwork volumes in the Corridor list.

- Specify the Sample Interval along the alignment for the analysis.

- In the Costs group, click the Haul cost box and type the cost to haul material along the alignment.

- To account for the cost to cut material from the ground and use material as fill, in the Cut cost box enter the cost to cut material from the ground. In the Fill cost box enter the cost to distribute and compact the fill material. The cut and fill costs are displayed in the properties of the corridor mass haul and in the corridor mass haul report.

- In the Earthwork Sites group do one of the following:

- Click the Use defined borrow/waste sites button to include earthworks sites that you have created using the Create Earthworks Site command in Site Mass Haul > Earthwork command, in the corridor mass haul calculations. Then check the Respect earthwork site capacities box to respect the volume capacities defined for each borrow site and waste site. If you leave this box unchecked, the analysis assumes that all borrow sites and waste sites have unlimited volumes of borrow material and unlimited capacity for waste. If the corridor mass haul analysis determines there is a surplus or deficit of material, a red warning flag displays in the mass haul diagram.

Note: Select these options (Use defined...sites and Respect...capacities above)if you will be using a material processing site. Otherwise, you will not get values when you run the Material Processing Report.

- Click Use Default borrow/waste to create default borrow and waste sites at the start and end of the corridor, and at the barrier. Default borrow and waste sites are only created when required.Then, in the Default borrow cost box type the default cost to borrow material. In the Default waste cost box type the cost to waste materials.

- Click the Use defined borrow/waste sites button to include earthworks sites that you have created using the Create Earthworks Site command in Site Mass Haul > Earthwork command, in the corridor mass haul calculations. Then check the Respect earthwork site capacities box to respect the volume capacities defined for each borrow site and waste site. If you leave this box unchecked, the analysis assumes that all borrow sites and waste sites have unlimited volumes of borrow material and unlimited capacity for waste. If the corridor mass haul analysis determines there is a surplus or deficit of material, a red warning flag displays in the mass haul diagram.

- In the Fill Materials group, do one of the following:

- Click the Respect defined fill materials button to use specific fill materials in the corridor mass haul calculations. The fill material is determined by the fill material specified for the corridor, and the materials specified in the template editor. Only individual material ordinates can be balanced. See help topic Understanding Materials in Mass Haul Analyses.

Note: Select this option (Respect...materials above) if you will be using a material processing site.

- Click the Use generic fill materials button to use any material cut from the surface, borrowed, or created at a processing site, as fill. The usable and unusable ordinates can be balanced in addition to the individual material ordinates.

- Click the Respect defined fill materials button to use specific fill materials in the corridor mass haul calculations. The fill material is determined by the fill material specified for the corridor, and the materials specified in the template editor. Only individual material ordinates can be balanced. See help topic Understanding Materials in Mass Haul Analyses.

- Click OK.

Dependencies:

The corridor mass haul analysis is dependent on:

- the corridor

- the original ground surface that the corridor references as Original ground in the Properties pane

- the native material specified for the corridor (if a corridor strata is not defined)

- materials in the strata and the corridor stratum settings (if a corridor strata is defined)

- the borrow material specified for the corridor

- the fill material/s specified for the corridor

If the surface, materials, or the corridor changes, the analysis must be rerun to be current. To do so, do one of the following:

- Right-click the analysis in the Project Explorer and select Refresh Mass Haul Analysis from the context menu.

- Click Refresh in the Mass haul diagram.